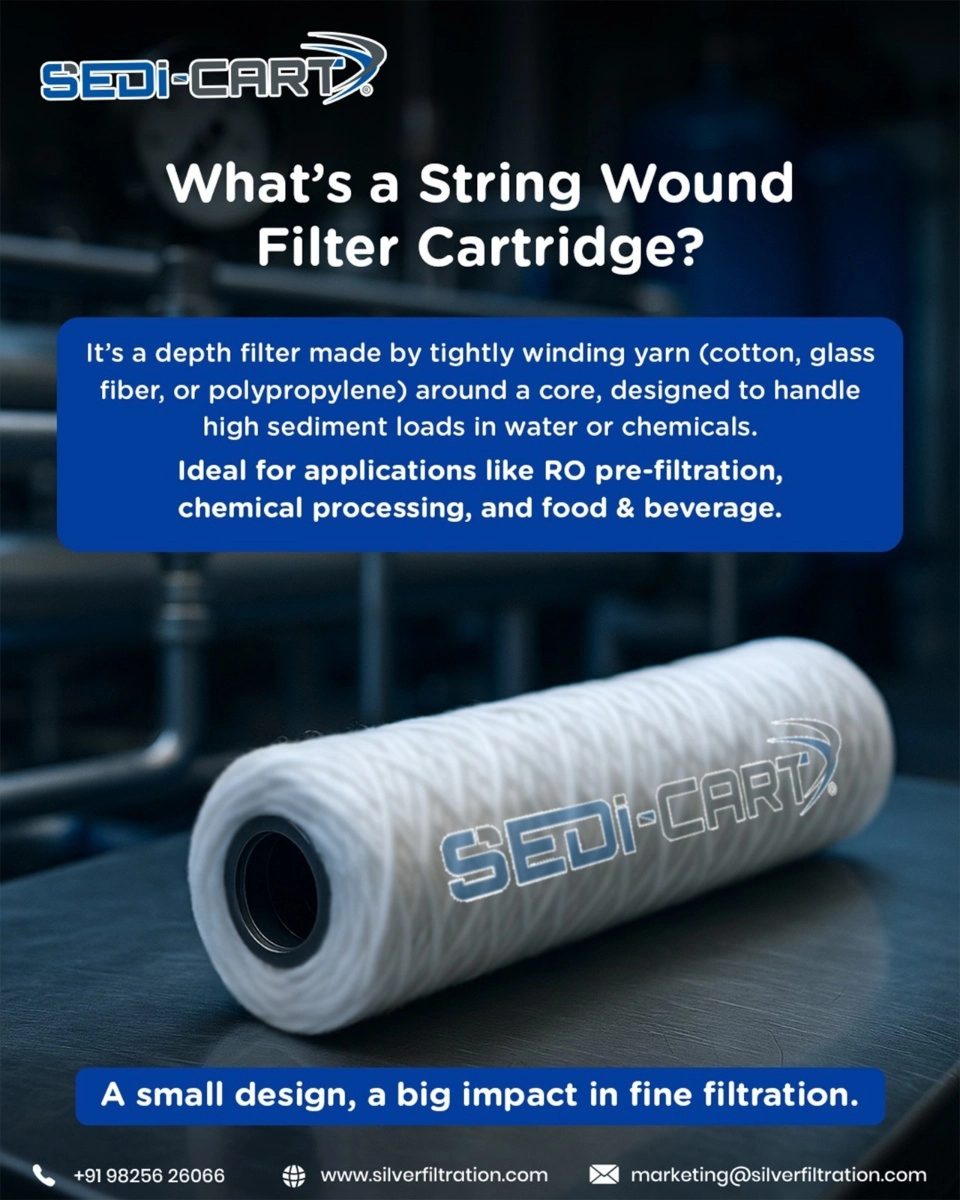

What's a String Wound Filter Catridge?

In the world of filtration, the String Wound Filter Cartridge stands out for its unique construction and efficiency. At its core, this depth filter is created by tightly winding yarn around a sturdy core, resulting in a multi-layered design that is particularly adept at capturing high sediment loads. Unlike other filter types, the string wound cartridge offers an extensive surface area, allowing it to effectively trap particles of varying sizes. This innovative design makes it an ideal choice for applications in reverse osmosis pre-filtration, chemical processing, and even the food and beverage industry, where purity and clarity are crucial.

Manufactured by industry leaders like Silver Filtration, India's largest meltblown filter cartridge manufacturer, these string wound cartridges promise exceptional performance and reliability. The winding process not only enhances the filter's ability to handle substantial sediment but also ensures that the cartridge can withstand significant pressure differentials. This resilience is vital for systems that demand consistent flow rates without compromising water quality. By incorporating string wound technology, Silver Filtration provides solutions that cater to diverse industries, ensuring that facilities can maintain operational efficiency while adhering to rigorous safety and quality standards.

Ultimately, the String Wound Filter Cartridge is not just a filtration device; it is a testament to engineering ingenuity that addresses the specific needs of various sectors. Its ability to manage high sediment loads while maintaining a consistent flow makes it indispensable for industries that rely on clean water and chemical integrity. As Silver Filtration continues to innovate and expand its product offerings, the string wound filter remains a cornerstone in the quest for effective and efficient filtration solutions. Embracing this technology means investing in reliability and quality, paving the way for a cleaner, safer future in water and chemical processing.